Em Guangxi, um novo marco foi alcançado na indústria de processamento de alimentos com a instalação e comissionamento bem-sucedidos de um freezer espiral duplo de 2 toneladas. Este equipamento avançado, também conhecido como congelador rápido de espiral dupla, marca uma atualização significativa na tecnologia de congelamento para a região, atendendo às crescentes demandas por soluções eficientes e de alta qualidade para preservação de alimentos.

O cliente, uma empresa de processamento de frutos do mar em Guangxi, procurou aprimorar sua linha de produção introduzindo um congelador espiral de última geração. O objetivo principal era permitir o congelamento rápido de produtos do mar, garantindo frescor e qualidade ideais, ao mesmo tempo em que atendia aos rigorosos padrões de segurança alimentar. Depois de avaliar diversas opções, a empresa optou por um explosor congelador de espiral dupla devido ao seu desempenho e eficiência superiores.

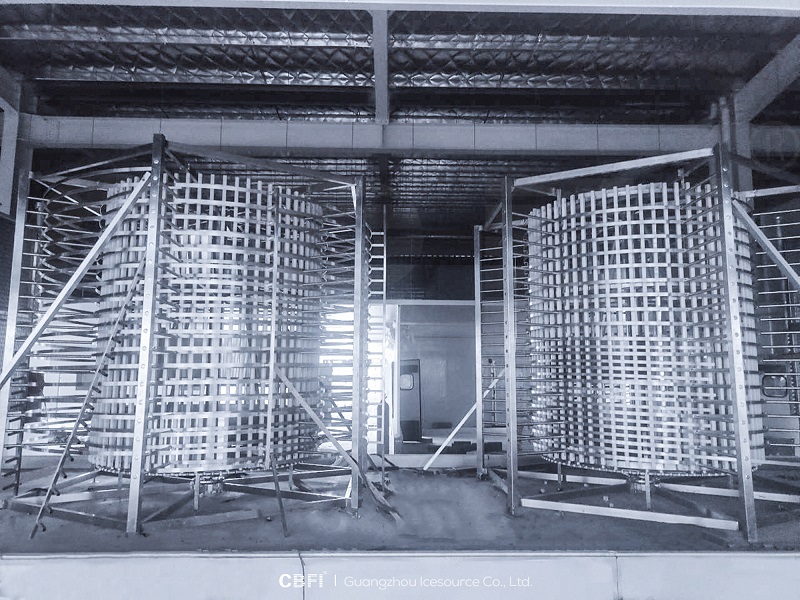

A instalação do congelador espiral duplo envolveu múltiplas etapas:

Depois de instalado, o freezer passou por um rigoroso processo de comissionamento. Os testes iniciais se concentraram na verificação do desempenho do sistema explosor congelador em espiral, garantindo que ele atingisse as temperaturas desejadas de forma rápida e consistente. Lotes de frutos do mar foram congelados usando o congelador espiral IQF e os resultados mostraram excelente qualidade do produto, sem grumos ou danos causados pela geada.

Também foram realizados testes de eficiência energética, revelando que os custos operacionais estão alinhados com o custo estimado do freezer espiral, tornando-o uma escolha altamente econômica para o cliente.

Durante a instalação, surgiram alguns desafios:

A adição do freezer espiral duplo de 2 toneladas aumentou significativamente a eficiência da produção do cliente. Os principais benefícios incluem:

A implantação bem-sucedida deste congelador espiral para venda posicionou o cliente como líder na indústria de processamento de frutos do mar em Guangxi. Estão em andamento planos para instalar unidades adicionais à medida que o negócio se expande. O cliente também pretende explorar recursos avançados de automação para otimizar ainda mais a produção.

A instalação e comissionamento do freezer espiral duplo de 2 toneladas em Guangxi ilustram o impacto transformador da moderna tecnologia de congelamento. Ao fazer parceria com fabricantes de freezers em espiral de renome, o cliente não apenas melhorou sua capacidade de produção, mas também estabeleceu uma referência de qualidade e eficiência no setor. Para empresas que buscam soluções de congelamento de ponta, investir em um congelador rápido em espiral ou congelador rápido em espiral é uma decisão que promete benefícios de longo prazo.