In the competitive world of ice production, especially for small ice factories, choosing the right equipment can make all the difference. The 10-ton integrated tube ice machine has become a popular option for smaller operations due to its impressive cost-effectiveness, energy efficiency, and space-saving design. This article will highlight the key benefits that make this ice machine a standout choice for small-scale ice production.

Small ice factories often face the challenge of balancing production capacity with limited budgets. The 10-ton integrated tube ice machine offers several advantages, making it an ideal solution for smaller operations.

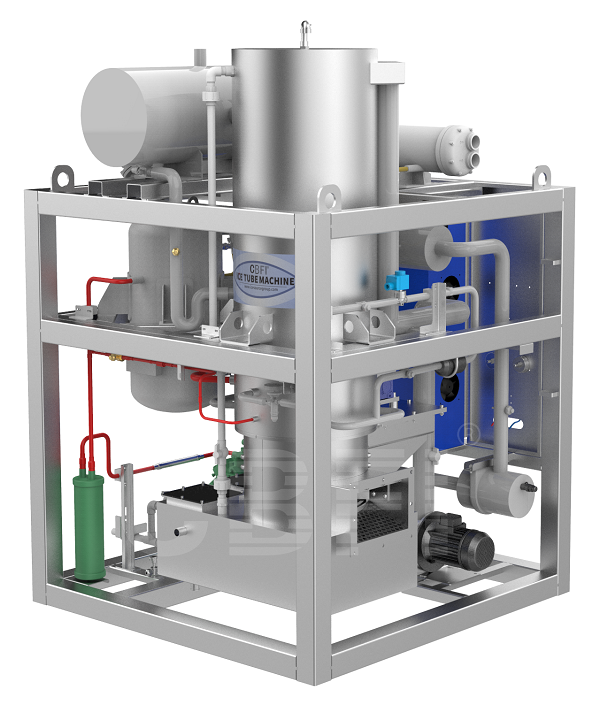

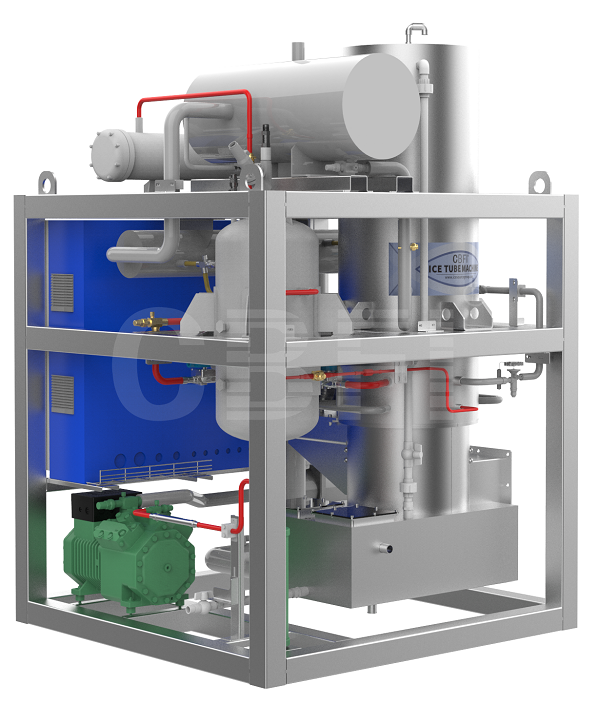

For small ice factories, cost-effectiveness is crucial. Investing in equipment can be a significant expense, and every dollar counts. The 10-ton integrated tube ice machine offers a low initial investment thanks to its all-in-one design. Unlike traditional systems that require separate components for different functions, this integrated model combines the evaporator, condenser, and compressor into one unit. This streamlined setup reduces both upfront costs and installation expenses, making it a more affordable choice for small ice factories.

Energy consumption is a major concern for small ice producers, as high energy bills can eat into profits. The 10-ton integrated tube ice machine is designed with energy efficiency in mind. By optimizing internal components, this machine minimizes energy waste, helping to lower electricity costs. Additionally, it operates with minimal noise and vibration, further enhancing its energy-saving capabilities. For small ice factories aiming to reduce long-term operational expenses, this machine offers a highly efficient solution.

In smaller ice factories, space is often limited. Traditional ice machines can take up significant floor space due to multiple components and separate cooling systems. The 10-ton integrated tube ice machine, however, features a compact design that consolidates all key components into a single unit, saving valuable space. This makes it an excellent choice for factories with limited production areas, allowing them to maximize available space for other operational needs.

Even though it is affordable, the 10-ton integrated tube ice machine does not sacrifice on the quality of the ice it produces. The machine produces clean, high-quality tube ice free from impurities, making it ideal for industries that require reliable, high-quality ice such as seafood processing, food preservation, and retail. Small ice factories can meet the needs of industries that demand high-quality ice without the need for larger, more expensive equipment.

Maintenance can be a challenge, particularly for small operations with limited resources. The 10-ton integrated tube ice machine is designed to be low-maintenance due to its fewer moving parts and sturdy construction. Its integrated design reduces the risk of mechanical failure, making it easier to clean and service. This results in reduced downtime, lower repair costs, and a longer lifespan, which is vital for small ice factories that cannot afford frequent interruptions to their production schedules.

The 10-ton integrated tube ice machine is specifically designed to meet the needs of small ice factories. Below are some ways this machine can help these businesses gain a competitive edge in the market:

A major challenge for small ice factories is scaling up production without making large investments. The 10-ton integrated tube ice machine allows small producers to meet higher demand without the need to purchase larger, more expensive systems. It strikes a perfect balance between capacity and affordability, enabling businesses to increase their production without overextending their budgets.

While larger suppliers may have more resources, small ice factories can still compete by offering competitive pricing without compromising on ice quality. By adopting the cost-effective 10-ton integrated tube ice machine, small operations can keep costs low while maintaining high-quality output. This makes it possible to expand their market reach and serve industries that require a steady supply of ice, such as food service providers, small retail outlets, and local businesses.

As small ice factories grow, it is essential to invest in machines that can scale with the business. The 10-ton integrated tube ice machine is not only an affordable solution for today but also a future-proof investment. Its low energy consumption, durability, and ease of maintenance ensure long-term savings and reliable performance, making it a smart choice for factories looking to stay competitive in the future.

The 10-ton integrated tube ice machine offers a perfect blend of cost-effectiveness, efficiency, and reliability. Its ability to produce high-quality ice at a low operating cost, combined with its compact design and ease of maintenance, makes it an ideal solution for small ice factories looking to remain competitive. With the growing demand for affordable, high-quality ice, the 10-ton integrated tube ice machine is well-positioned to revolutionize small-scale ice production.